All About Electric Cell Sampler. What is it and Its Features

Sampling is a crucial aspect in maintaining the overall quality of a product. Especially in industries like petrochemical or Oil and Gas that deal with liquids and gaseous states, sampling is required so that the whole product turns out to be of good quality. The electric cell sampler is the process which is simply obtaining a sample directly from the process pipeline stream and performing different quality tests on it.

An inline sampler is a method that tests a small volume and can be used as loading arm sampling while an automatic sampler will collect the sample automatically once the target accumulation is achieved. If we talk about an electric cell sampler, then it comes under an automatic sampling system.

In this article, we will know about an electric cell sampler, its working and its features. So, let’s get straight to it

What is an Electric Cell Sampler and How Does it Work?

You now might have already known the difference between an inline sampler and an automatic sampler. An inline sampler does require manual effort to collect the sample while in an automatic sampling system, it gets collected and transported automatically once the target accumulation is achieved.

An electric cell sampler is a type of automated sampling method because it captures samples in time for the actual flow rate. The primary benefit of this sampler is that it can take up to 10,000 grabs per batch and provides a representative sample for further testing and analysis. This makes it efficient.

Well, you may now know the purpose of using electric cell samplers. Let us try to understand the working of these samplers.

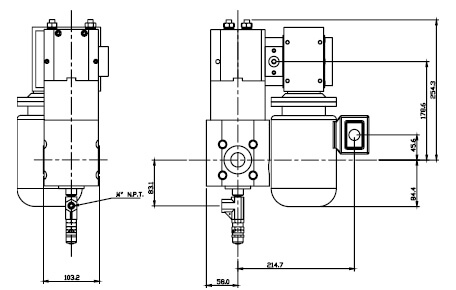

It is an automatic sampler with an electrically actuated precision metering pump. The system contains a tubular stem with an inner concentric capture tube and a piston. Also, each sampling cycle is a 3-step process:

- A piston and capture tube is in a fully up position, thereafter the sample flows through the chamber. Then NRV (non-return valve) is closed.

- Now the capture tube descends and grabs the sample volume. The piston remains up and NRV remains closed.

- PIston with capture tube descends to expel the grabbed sample via NRV to the sample receiver.

The above-mentioned steps show the functioning of an electric cell sampler. However, for operation, an electric cell sampler may also require an additional electrical control box.

Let us look at some features of an electric cell sampler.

Features of Electric Cell Sampler

Now that we know the basic functioning and purpose of using an cell sampler, let us understand some of its features that make it more efficient.

- The sampler has a non-return valve (NRV) that avoids the separation of immiscible constituents i.e water in crude oil during the sampling cycle.

- The sampler has no selective water retention ports within its cell.

- It has a high grab volume of +/-0.5%.

- The sampler is of stainless steel.

- Accurately built to conduct accurate sampling.

- Sampler can be operated at up to 15 grabs/min rate.

- Material selection that meets NACE 0715R requirements.

The main benefit of using an electric cell sampler is to collect samples in a fast flow loop (bypass) from the pipeline. The sampler has a flow cell integrated with a sample collection mechanism which leads to more system integrity, servicing and reliability.

Wrapping Up

Hopefully, the article helped you understand inline sampling, automatic sampling and how electric cell sampling is an efficient choice when it comes to sampling. You can reach out to manufacturers like OGSI to know more about which metering system and sampling systems should you use for your business.